Customer Loyalty & Rewards Program

FAQ's

When did the Loyalty & Rewards Program begin?

We rolled out the program in the Spring of 2022

How do I become a member of the Loyalty & Rewards Program?

If you purchased a production or custom Schenk knife between January and October 2022, you were automatically entered into the program

If you purchased, or were gifted, a production or custom Schenk knife after October 2022, there should have been a product registration QR code in the knife box. If you followed the code and registered your knife, you were entered into the program

What's in it for me?

By entering into the program, you may occasionally receive Schenk Knives swag, and you're eligible for the Christmas Custom Knife Giveaway

What kind of swag can I get from being in the program?

Schenk swag includes, but is not limited to: custom stickers, keyrings, wallets, coasters, hats, shirts, and hoodies

What is the Christmas 2022 Custom Knife Giveaway?

In December of each year, one name will be drawn from all of the eligible program participants and the winner will receive a custom Schenk knife, valued between $400 and $500

How many times can I enter my name in the custom knife giveaway?

Your name is entered one time for every knife purchase you've made or registered in 2022

Can I enter the drawing if I received a knife as a gift?

Yes, as long as you registered your product via the QR code in the knife box. If your box did not have a QR code, it was purchased before the program was rolled out and is not eligible for registration

When will the winner of the giveaway receive the custom knife?

The winner of the custom knife giveaway will be notified immediately following the drawing and the knife will be shipped out the following day

Are there any other benefits from registering my knife and entering the program?

Yes, as a member of the program, you may be notified when new products and custom knives are rolled out, and when out-of-stock models come back in stock

You may also be notified when new blog posts are made and when new podcast episodes become available

Can I opt out of product notifications?

Yes, simply reply to your most recent email and your name will be removed from the mailing list

If I opt out of product notifications, am I still eligible for the custom knife giveaway?

Yes, you will still be entered into the custom knife drawing in December of each year

I still have questions, who can I speak with?

For more information, please call Matt (208-523-7436 ext 1003) or email

matt@schenkknives.com

Every Schenk brand knife comes with a RazorLife Warranty. Your knife will be re-sharpened to a full factory edge, including a leather strop and hone. If the razor edge has been lost because of heavy use or neglect, simply ship your knife back to the factory for inspection, cleaning, and re-sharpening. Please allow 2-5 business days for return. There is no return shipping cost to you for the service.

Securely ship your knife, postage paid and insured. Schenk Knives is not responsible for any product lost in shipping. For questions regarding the Schenk Knives RazorLife Warranty, please contact us by email or phone.

Each knife that is sharpened at our factory goes through a 5-step process to ensure it has a razor sharp edge when it leaves.

Schenk Knives

Atten: RazorLife

4570 N. Haroldsen Drive

Idaho Falls, ID 83401

Accu-Traction was developed from years of hunting experience. Accu-Traction is placed towards the tip of certain hunting knife models that can be used with a forward or pinch grip. This forward grip allows you to safely place your index finger on the top of the spine near the tip.

Accu-Traction helps in two areas. First, it gives your index finger extra traction. Often times while skinning an animal, your blade is covered in blood, making the knife slippery. Accu-Traction provides that extra purchase needed to safely and confidently get the job done. Second, it helps you find the point of your knife, without cutting yourself, even when you can’t see the knife. As you run your index finger down the spine, Accu-Traction let’s you know the you’re getting close to the sharp tip of the blade.

MID TECH | HANDCRAFTED

All of our knives are handcrafted in our factory in Idaho Falls, ID.

BLADE GRINDS

HOLLOW GRIND - A hollow grind is commonly used in today's production knives. The grind is highly favored by hunters and sportsmen for its razor sharp edge and its versatility in skinning and butchering meats after a hunt. A hollow grind reduces knife edge thickness and is a very sharp but also is more prone to rolling or damage when put under heavy cutting.

FLAT GRIND - A flat grind has a stronger edge due to the greater thickness behind the sharpened edge. Re-sharpening thickens the edge faster and it takes a bit longer to re-sharpen. A great choice for general heavy use.

CONVEX - A convex grind is very strong with a well-supported cutting edge for heavy duty use and cutting. Edge thickens directly behind the sharpened edge. With heavy use and over time the blade edge will begin to thicken and become harder to re-sharpen. A great choice for heavy duty use.

SCANDI - A scandi grind has the strongest blade edge. The scandi grind is popular among survival and bushcrafting groups. When ground correctly, it allows for a true zero degree edge. Although this blade edge is strong and easy to re-sharpen, it does dull faster than other blade grinds.

HEAT-TREATING

SALT BATH FOR DAMASCUS AND 52100 STEELS - Salts are heated to a molten 1500 degrees. The knife blade is lowered into the salt bath and soaked, then quickly removed, agitated and quenched in low temperature molten salts for 1 min. The blades are removed from the low temperature salts, and while still soft, straightened if needed. The blade is then placed back into low temperature salts or a heat treating kiln and allowed to soak at lower temperature for several hours. This tempering process removes much of the internal stress in the steel and tempers or slightly softens the blade to a perfect state to hold a great edge and not be too brittle.

When the process is done in salt baths it will yield a blade that is approximately 20% tougher, has greater edge holding ability, and no hardening scale to remove from the high temperature hardening process.

This process is done in house and for O.E.M. customers around the country.

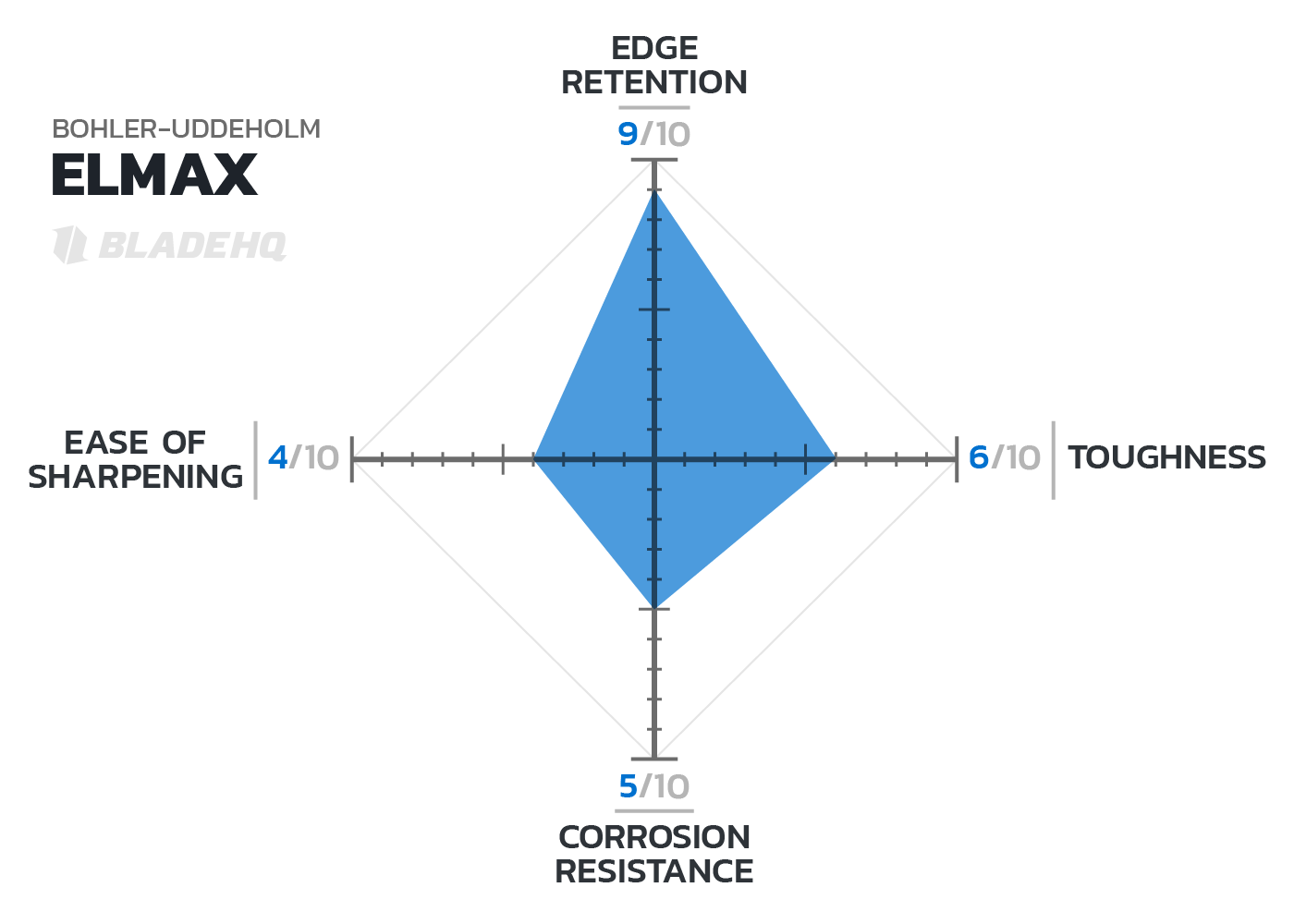

ELMAX STAINLESS POWDERED STEEL -The blades are placed in a vacuum high temperature heat treating kiln. The blades are soaked at a temperature around 2000 degrees F. Within the kiln the blades are quickly cooled and become very hard. The blades are then reduced to minus 320 below zero (cryo quenched), held for a period of time and brought back to room temperature where they are tempered at a low temperature for several hours. Our Elmax is sent to Peters Heat-Treating who we feel is the best in the industry for heat-treating Elmax.

Blade HQ offers some fantastic information and visuals regarding Elmax. (www.bladehq.com)

KNIFE HANDLE MATERIALS

G-10 - A composite made of layers of glass cloth and epoxy resin. It can then be colored if desired. It is then compressed and baked. The resulting material is very hard, lightweight, strong and attractive. Our top choice for a using on production knives.

MICARTA - A composite made of layers of cloth, paper or canvas and phenolic resin. Micarta is a very tough and durable material that makes for a great choice for an economy priced knife handle.

RARE WOODS - We use most any wood but prefer to use stabilized domestic burls, that we harvest and stabilize in-house, such as: box elder, maple, California buckeye, black ash, redwood, walnut and many others. Stabilizing is a process whereby the burl has been dried then processed using a combination of vacuum, liquid epoxy resins and curing. The dead air space in the wood has now been replaced by cured epoxy resins. To finish the handle you sand to 600 grit then buff on a white compound. This is one of our favorite handle materials to use on custom and limited edition knives.

MISC. HANDLE MATERIALS - We commonly use axis stag, elk antler, deer antler, moose antler, bones, fossil ivory, water buffalo horn, mammoth ivory, giraffe bone and many other exotics materials.

KNIFE SHEATHS

LEATHER - We make all leather sheaths in house using domestic saddle skirting from Wickett & Craig. Leather can be carved, tooled and stamped. All knife sheaths are glued, stitched, assembled, wet formed, dyed, oiled and finished giving each Schenk Knife a custom, handcrafted leather sheath.

KYDEX - A thermoforming plastic that is used on many tactical knives, neck sheaths, hunting knives, and divers knives. Many colors and texture patterns are available. Kydex sheaths are generally held together with screws and rivets and need steel parts for belts clips and other fittings.